Download PDF: SPFA Technical Bulletin T0004 v1.01 Duplex Stainless Steel

Duplex Stainless Steels are classified as Austenetic-Ferretic grades as their metallurgical structure consists of two phases: austenite and ferrite in roughly equal portions.

They were developed in the late 1970s with excellent resistance to stress corrosion cracking and improved pitting resistance than standard Austenitic Grades.

Duplex Stainless Steels contain relatively high chromium (between 18 and 28%) and moderate amounts of nickel (between 4.5 and 8%). The nickel content is insufficient to generate a fully austenitic structure and the resulting combination of ferritic and austenitic structures is called duplex. Most duplex steels contain molybdenum in a range of 2.5 – 4%.

Basic properties

- High resistance to stress corrosion cracking

- Increased resistance to chloride ion attack

- Higher tensile and yield strength than austenitic or ferritic steels

- Good weldability and formability

Common uses

- Marine applications, particularly at slightly elevated temperatures

- Desalination plant

- Heat exchangers

- Petrochemical plant

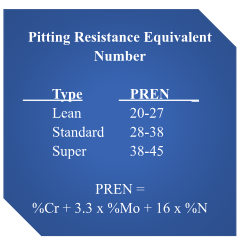

Pitting Resistance Equivalent Number

A factor in selecting a duplex grade might be the Pitting Resistance Equivalent Number. PREN is frequently specified when stainless steels will be exposed to seawater or other high chloride solutions.

In some instances, stainless steels with PREN-values >32 may provide useful resistance to pitting corrosion in seawater but is dependent on optimal conditions. However, crevice corrosion is also a significant possibility and a PREN >40 is typically specified for seawater service.

Lean Duplex with lower Nickel and Molybdenum may be more economical especially in tank & structural applications. Whereas Super Duplex with elevated Chromium, Nickel and Molybdenum (and some with added Copper & Tungsten) are advisable for higher corrosion & wear applications.

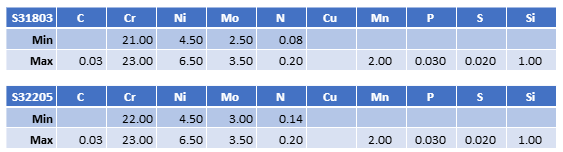

UNS S31803 / S32205 Standard Duplex

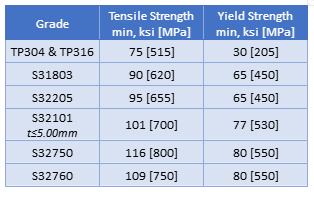

- Superior corrosion resistance to 316L and 317L combined with high strength. Both duplex grades achieving minimum 65ksi [450MPa] yield strength.

- Excellent pitting corrosion resistance and stress corrosion resistance.

- The addition of Nitrogen content helps in increasing the PREN value of the material.

- Typically used in heat exchangers, gas scrubbers, fans, chemical tanks, flowlines, marine and refinery applications.

- Commercially “Duplex” grade is referred to as 2205. This actually refers to both versions S31803 and S32205. In fact most piping material is produced as dual grade S31803/S32205.

- Dual certified S31803/S32205 is the most universally stocked of all the Duplex grades, with a wide range Pipes Fittings and Flanges available for prompt delivery.

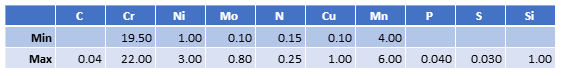

UNS S32101 Lean Duplex

- Corrosion resistance approaching that of 316, with higher strength and stress corrosion cracking resistance.

- Suited for storage tanks and structural applications.

- Not generally stocked in piping products.

- Also commonly known as Lean Duplex 2101 LDX.

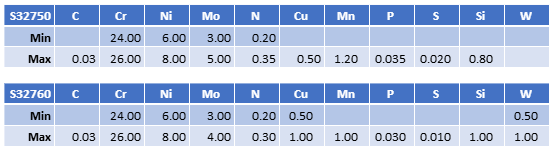

UNS S32750 and S32760 Super Duplex

- Extremely high resistance to corrosion in severe marine, chloride and acid environments.

- Superior high strength with both super duplex grades achieving minimum 80ksi [550MPa] yield strength.

- Achieve a PREN (Pitting Resistance Equivalent Number) of more than 40 and a minimum yield strength of 80KSI.

- The addition of copper and tungsten in S32760 give the alloy resistance to mineral acids such as sulfuric and hydrochloric.

- Suitable for heat exchangers, reactors, pipework etc.

- S32750 is also commonly known as Super Duplex 2507 and is the most commonly stocked grade of Super Duplex readily available in Pipes, Fittings and Flanges.

- S32760 is also commonly known as Zeron 100, or URANUS 76N.

Tensile & Yield Strength

All duplex grades exhibit high yield strength, therefore greater forces are required for the cold forming and will require larger capacity equipment than would be required for austenitic steels. Processes such as stretch forming, deep-drawing and spinning are more difficult to perform.

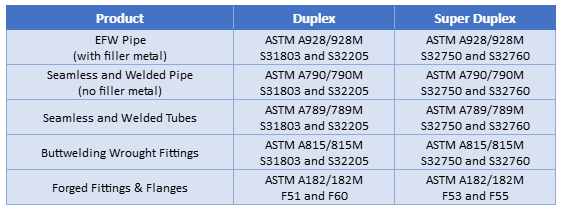

Material Standards

Duplex and Super Duplex grades are commonly supplied by SPFA in these material standards and grades, others available on request:

Image:

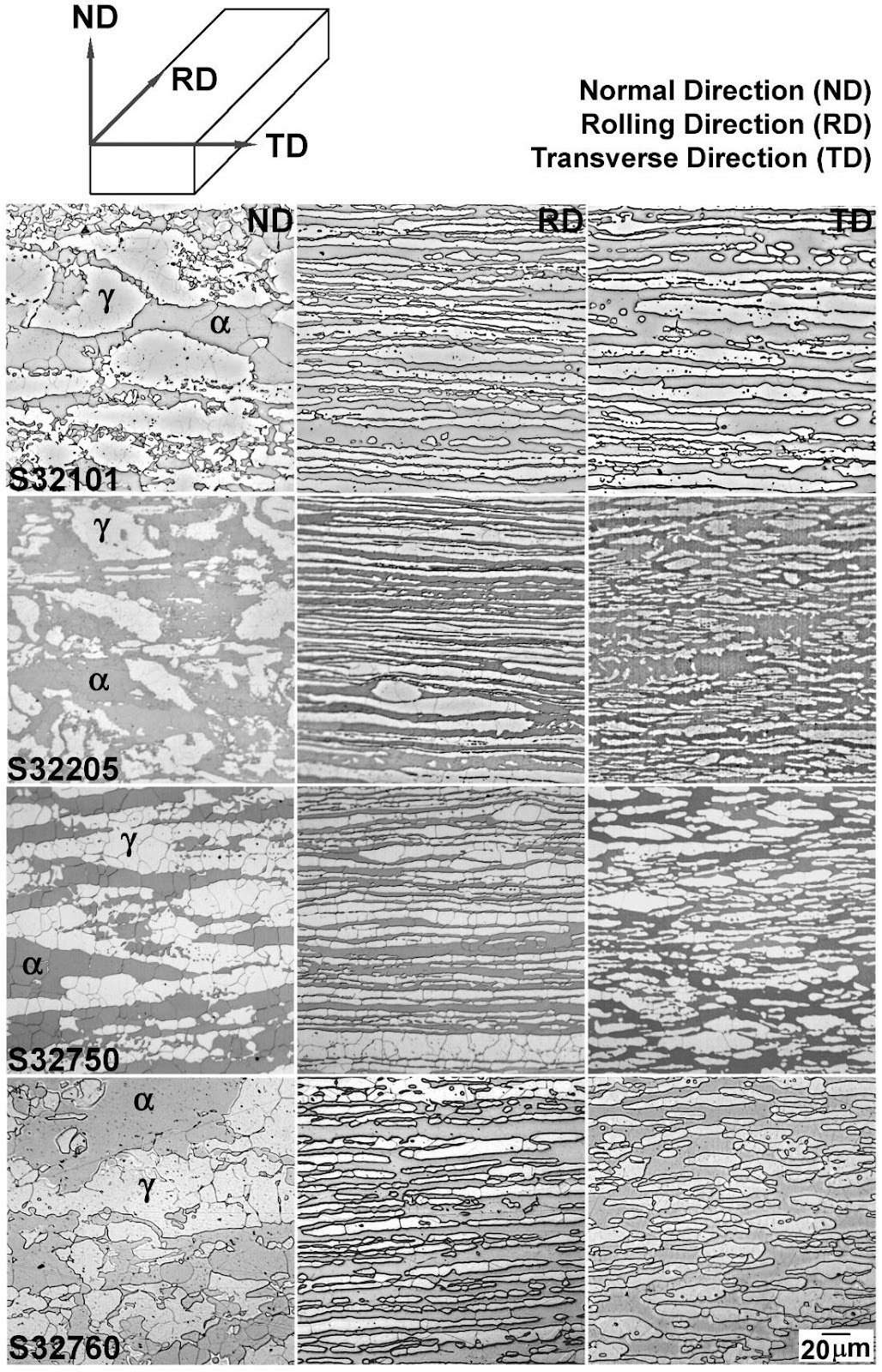

Microstructures of four kinds of duplex stainless steel in normal, transverse, and rolling directions

Ferritic: alpha iron (α-Fe)

Austenitic: gamma-phase iron (γ-Fe)

Credit: Tiago Felipe de Abreu Santosa, Edwar Andrés Torres Lópezd, Eduardo Bertoni da Fonsecaa & Antonio Jose Ramireza, CC BY 4.0 <https://creativecommons.org/licenses/by/4.0>, via Wikimedia Commons